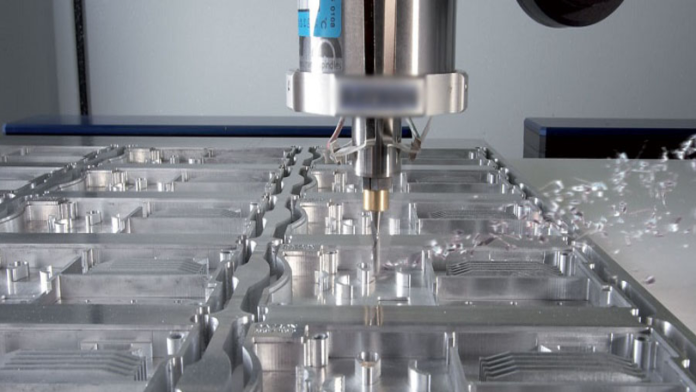

Aluminum, a versatile metal, is commonly used in many industries for its lightweight, strength, and durability. Choosing the right aluminum alloy can greatly impact the performance, cost-effectiveness, and efficiency of the final product. However, with so many aluminum alloys available in the market, it can be challenging to select the one that best suits your needs.

In this article, we will discuss the factors you need to consider while choosing the right aluminum alloy.

Strength

The strength of an aluminum alloy is an essential factor to consider, depending on the application. The higher the strength, the better the performance, and the lesser the chance of damage or breakage. However, stronger aluminum alloys can be more expensive than the weaker ones. Depending on your budget and the performance required, you can choose the best aluminum alloy. For example, 6061 aluminum alloy, which is the most common and versatile alloy, offers good strength, formability, and weldability.

Corrosion Resistance

The ability to resist corrosion is a crucial factor for aluminum alloys that are used in marine environments or places exposed to acidic substances. Aluminum alloys with high corrosion resistance are usually more expensive and require specialized treatment. For example, 5052 aluminum alloy, which is widely used in marine environments, offers excellent corrosion resistance and high strength-to-weight ratio.

Formability

Depending on the application, aluminum alloys need to have specific formability properties. Some aluminum alloys can be easily shaped into specific forms without cracking, while others can’t. 3003 aluminum alloy, which is often used for fuel tanks, refrigeration, and cooking utensils, has excellent formability.

Weldability

Weldability is a critical factor to consider when selecting aluminum alloys as some alloys are difficult to weld using specific methods. 6063 aluminum alloy, which is commonly used in architectural applications, offers excellent weldability, strength, and corrosion resistance.

Cost

Lastly, the cost of an aluminum alloy is another factor to consider. The more intricate the design, the greater the cost of the aluminum alloy chosen. The prices of aluminum alloys differ significantly depending on the alloy grade, production complexity, and distribution. Therefore, consider your budget and the performance criteria before selecting the appropriate aluminum alloy.

Thermal Conductivity

Aluminum alloys have excellent thermal conductivity properties. Depending on the application, it may be important to select an alloy with high thermal conductivity to efficiently transfer heat or dissipate it.

It’s important to consider these factors when to choose the right Aluminum alloy and consult with material experts or engineers who can provide guidance based on your specific requirements.

Conclusion

In conclusion, when choosing the right aluminum alloy, it’s crucial to consider the factors mentioned above and their relative importance for your project. It’s always best to compare the characteristics, advantages, and disadvantages of different aluminum alloys before making a final decision. Moreover, seek the advice of professionals, such as suppliers, engineers, or designers, who can help you select the most appropriate aluminum alloy for your specific application. By choosing the right aluminum alloy, you can achieve significant performance benefits, cost-effectiveness, and durability.