Choosing the right steel pipe for your project is a critical decision that can significantly impact the success of your operations. The EN 10255 steel pipe, known for its durability and versatility, is a popular choice among many industries. However, with various specifications and grades available, Choosing the right steel pipe can be a challenging endeavor. This comprehensive guide aims to streamline the selection process and provide you with the necessary information to make a well-informed decision.

Understanding Your Requirements

Before diving into the selection process, it’s crucial to understand your specific needs. What is the purpose of the pipe? Will it be used for plumbing, construction, or oil and gas transportation? The application will largely determine the type of pipe you need. For instance, if you’re dealing with high-pressure fluids, you’ll need a pipe with a high yield strength. Understanding your requirements is the first step towards finding the perfect EN 10255 steel pipe.

Key Factors to Consider

When choosing an EN 10255 steel pipe, several factors come into play. These include the pipe’s diameter and thickness, material grade and quality, coating, and surface finish. Let’s delve into these aspects.

Pipe Diameter and Thickness

The diameter and thickness of the pipe are critical factors that determine its capacity and pressure handling ability. Larger diameters and thicker walls can handle higher pressures, making them suitable for heavy-duty applications. However, they also increase the pipe’s weight and cost. Therefore, it’s essential to strike a balance between performance and practicality.

Material Grade and Quality

EN 10255 steel pipes come in various grades, each with its unique properties. Higher grades typically offer better performance but come at a higher cost. The quality of the material also plays a crucial role in the pipe’s durability and longevity. Always opt for pipes from reputable manufacturers to ensure high-quality products.

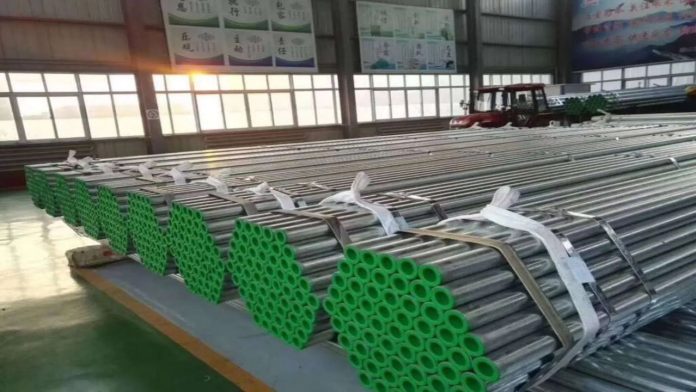

Coating and Surface Finish

The coating and surface finish of the pipe can affect its resistance to corrosion and wear. Pipes with a galvanized coating, for instance, offer excellent protection against rust, making them ideal for outdoor applications. The surface finish, on the other hand, can affect the pipe’s aesthetic appeal and its ability to bond with other materials.

Evaluating Application-specific Considerations

Apart from the general factors, some application-specific considerations might influence your decision. For instance, if the pipe will be used in a corrosive environment, you might need a pipe with a special corrosion-resistant coating. Similarly, if aesthetics are a concern, you might prefer a pipe with a polished finish.

Consulting with Experts and Suppliers

Given the technical nature of steel pipes, consulting with experts and suppliers can be extremely beneficial. They can provide valuable insights into the latest trends and advancements in the industry, helping you make an informed decision. Moreover, they can offer personalized recommendations based on your specific needs and budget.

Making the Final Selection

After considering all these factors, you’re now ready to make the final selection. Remember, the right EN 10255 steel pipe is not necessarily the most expensive one, but the one that best fits your requirements. Don’t hesitate to ask for samples or conduct tests to ensure the pipe meets your expectations.

Conclusion: Finding the Perfect EN 10255 Steel Pipe

In conclusion, choosing the right EN 10255 steel pipe involves a careful evaluation of your needs and a thorough understanding of the product’s specifications. By considering the factors mentioned above and consulting with experts, you can find the perfect pipe that not only meets your requirements but also offers the best value for your money. Remember, the right choice can significantly enhance the efficiency and longevity of your operations, making it a decision worth investing your time and effort in.